Welcome to the official website of Xidi laboratory, the laboratory design and decoration recognize Xidi!

|

|

Home >> News >> Technology

文章出处:Technology|阅读量:982|发表时间:2021-03-11

Food safety has always been one of the people's livelihood issues that the country focuses on. my country’s policy clearly stipulates that regular food factories must build clean workshops and operate production in clean workshops to effectively reduce the deterioration of the products produced and prolong the food shelf life. Conventional food purification workshops need to meet the 100,000-level air purification standard (a few food factories require it to reach 10,000-level). CEIDI Xidi uses the most commonly used 100,000-grade food workshop in most food purification workshops on the market to illustrate, what is a 100,000-grade clean workshop? To put it simply, the number of particles with a diameter of ≥0.5μm per cubic meter of air in the workshop is not more than 3.52 million. The less the number of particles in the air, the less the number of dust and microorganisms and the cleaner the air. The 100,000-grade clean workshop also requires 15-19 air exchanges per hour in the workshop, and the air purification time after complete air exchange does not exceed 40 minutes.

Area division of clean workshop in food factory

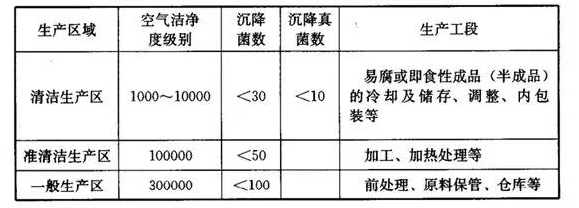

The clean workshop of a general food factory can be roughly divided into three areas: general operation area, quasi-clean area, and clean operation area.

1. General operation area (non-clean area): general raw material, finished product, tool storage area, packaging finished product transfer area and other areas with low exposure risk of raw materials and finished products, such as outer packaging room, raw and auxiliary material warehouse, packaging material warehouse, outside Packaging workshop, finished product warehouse, etc.

2. Quasi-clean area: the second is required, such as raw material processing, packaging material processing, packaging, buffer room (unpacking room), general production and processing room, non-ready food inner packaging room and other finished product processing but not directly exposed areas.

3. Clean operation area (clean room): Refers to the highest sanitary environment requirements, personnel and environmental requirements are high, and must be disinfected and changed before they can enter, such as: raw materials and finished products exposed processing areas, cold processing rooms for eating food, ready-to-eat food The cooling room, the storage room for ready-to-eat foods to be packaged, the inner packaging room for ready-to-eat foods, etc.

Different production areas and air cleanliness levels of food factories

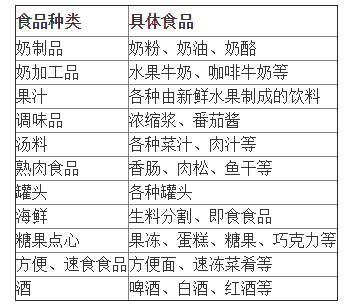

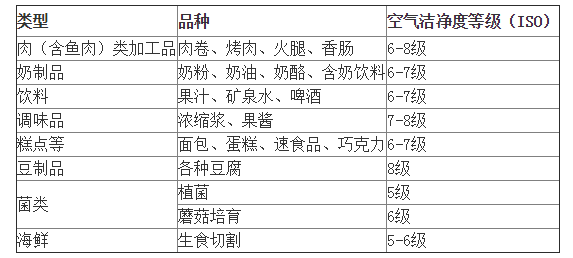

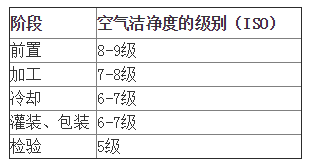

In order to prevent the whole process of food production from being contaminated by microorganisms, raw materials, water, equipment, etc. must be treated, and the environment of the production workshop is also an important condition. The following are the types of food produced in the clean room, as well as the cleanliness required for various food production and the cleanliness of different stages of food production, organized by CEIDI.