Welcome to the official website of Xidi laboratory, the laboratory design and decoration recognize Xidi!

|

|

Home >> News >> Technology

文章出处:Technology|阅读量:812|发表时间:2021-03-19

Photoelectric workshop purification engineering refers to the semiconductor, microelectronics, optoelectronic technology, optical instruments, PCB, food, mold and other projects in the purification workshops or electronic laboratories of electronic factories of different levels. Optical microelectronics purification engineering, also known as clean room or clean room, is now an indispensable and important facility in precision manufacturing, semiconductor, optical manufacturing, liquid crystal manufacturing, circuit board manufacturing and medicine, biochemistry, food manufacturing and other industries. In recent years, due to technological innovation and development, the demand for high precision and miniaturization of products has become more and more urgent. For example, the research and manufacture of super-large integrated circuits has become a project that countries all over the world attach great importance to in scientific and technological development. According to industry standards, the purification level ranges from 100,000 to 300,000. The degree of purification also directly affects the quality of electronic products.

I.What are the functional areas generally included in the optical microelectronics purification project:

1.Clean production area

2.Management area (including office, duty, management and rest, etc.)

3.Clean auxiliary rooms (including personnel purification rooms, material purification rooms and some living rooms, etc.)

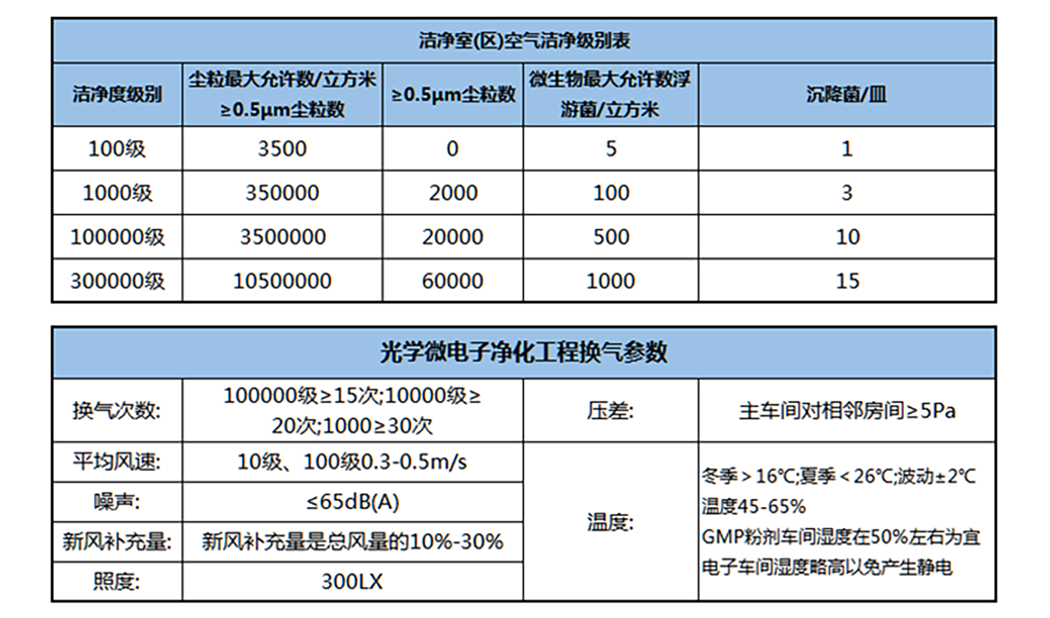

II.Standard parameters of electronic laboratory purification:

Photoelectric laboratory purification project: electronics factory/electronic laboratory decoration design

III.General structural materials for electronic laboratories:

1.The return air duct is made of hot-duty zinc sheet, and is attached with flame-retardant PF foamed plastic sheet with good purification and heat preservation effect.

2.The high-efficiency air outlet uses a stainless steel frame, which is beautiful and clean, and the perforated mesh plate uses a painted aluminum plate, which is not rusty or dusty, and should be cleaned.

3.The ground can be made of epoxy artesian floor or high-grade wear-resistant plastic floor. Anti-static type can be selected if anti-static requirements are required.

4.The walls and roof panels of the purification plant are generally made of 50mm thick sandwich color steel plates, which are characterized by beautiful appearance and strong rigidity. The arc wall corners, doors, window frames, etc. are generally made of special aluminum oxide profiles.

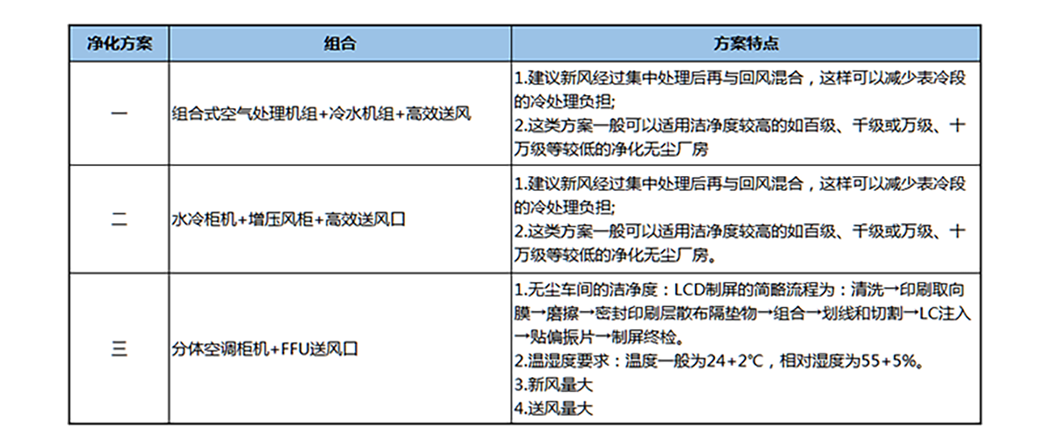

IV.Ceidi sub-factory/electronic laboratory purification air-conditioning program

Photoelectric laboratory purification project: electronics factory/electronic laboratory decoration design

Option 1: At present, it is the most traditional design solution for purifying air-conditioning. The combined air handling unit contains various functional sections, such as primary filter section, mixing section, surface cooling section, medium efficiency filter section, secondary return air section (or intermediate section) humidification section, heating section, fan section, etc. The cold source is mainly provided by the chiller. Scheme 2: Compared with scheme 1, scheme two is a relatively simple clean air conditioning design scheme. Not only can the area of the machine room be greatly reduced, but also the water-cooled cabinet can be arranged in a smaller purification workshop or in the machine room according to the specific situation. At the same time, the pressurized air cabinet can be arranged in the machine room or hung in the machine room or in the machine room. Inside the mezzanine.

Solution 3: Mainly used in dust-free workshops that do not require high indoor temperature and humidity accuracy, and it is the simplest air conditioning solution. The split air-conditioning cabinet can be directly arranged in the workshop, and surrounded by color steel, and the return air vent (with primary effect filter) is opened on the color steel plate at the return air outlet of the cabinet; the fan filter unit FFU is evenly arranged on the ceiling smallpox.

V.Ceidi electronic laboratory decoration project case

Ceidi has a wealth of experience in the decoration of electronics factories and electronic laboratories, such as BYD factory, Ningbo Delangneng Lithium Battery Technology Co., Ltd., Narada Battery, etc. Since the BYD factory has signed a confidentiality agreement with Xidi, there is no internal picture here. Delangneng was established in Fengxian District, Shanghai in October 2001, and successively established production bases and sales centers in Shanghai, Shenzhen, Zhangjiagang, Ningbo, and Tianjin. The industry focuses on battery cell manufacturing, and gradually extends to mid-downstream system integration business. Now it has become a well-known domestic green energy solution provider. The industry covers power lithium-ion batteries, battery control systems, civilian batteries and related product development and design. , Production, sales and service.

The above is about the air-conditioning installation plan for the purification project of the electronic workshop. CEIDI Xidi Purification specializes in the design and construction of air purification and other projects. It has served a number of industries including electronic dust-free workshops, medical clean workshops, 10,000-level coating clean rooms, cosmetics purification workshops, and 10,000-level medical equipment dust-free workshops. Food clean room. He has provided high-quality products and engineering services for the construction of clean workshops for leading biomedical companies in the industry, and has won a good reputation and has become a satisfactory and trustworthy partner for customers.