Welcome to the official website of Xidi laboratory, the laboratory design and decoration recognize Xidi!

|

|

Home >> News >> Technology

文章出处:Technology|阅读量:1316|发表时间:2021-05-13

The area of the beverage/liquor/canned food production workshop corresponds to the production process. The general principle is: make full use of the limited space and rationally design the production process layout. The interior of the workshop is basic, with smooth drainage, non-slip ground, firm and impervious, flat, no stagnant water, corrosion-resistant materials, and kept clean. The outlet of the workshop and the drainage and ventilation places connected to the outside world are installed with anti-rodent, anti-fly, and anti-insect facilities , The interior walls, ceilings, doors, and windows of the workshop are constructed with materials that are waterproof, mildew-proof, non-shedding, and easy to clean. Wall corners, ground corners, top corners, etc. are treated with aluminum arcs. In this article, CEIDI Xidi takes the brewery as an example, and the relevant knowledge of the design and decoration of the popular science craft brewery.

According to the country’s food (beverage) production licensing rules, the clean room environment of the food (beverage) workshop is controlled to reach the 10,000 or 100,000 level air purification standard. The aseptic clean workshop should be isolated from the outside world and cannot be passed through or affected by others. Factor interference. The brewery also designed and decorated with reference to the detailed rules.

Experience in space design and planning of brewery:

1. When designing space, CEIDI designers generally divide the factory area into: main production workshop, auxiliary workshop, power workshop, warehouse and yard part, three waste treatment part, office area part, and display area part.

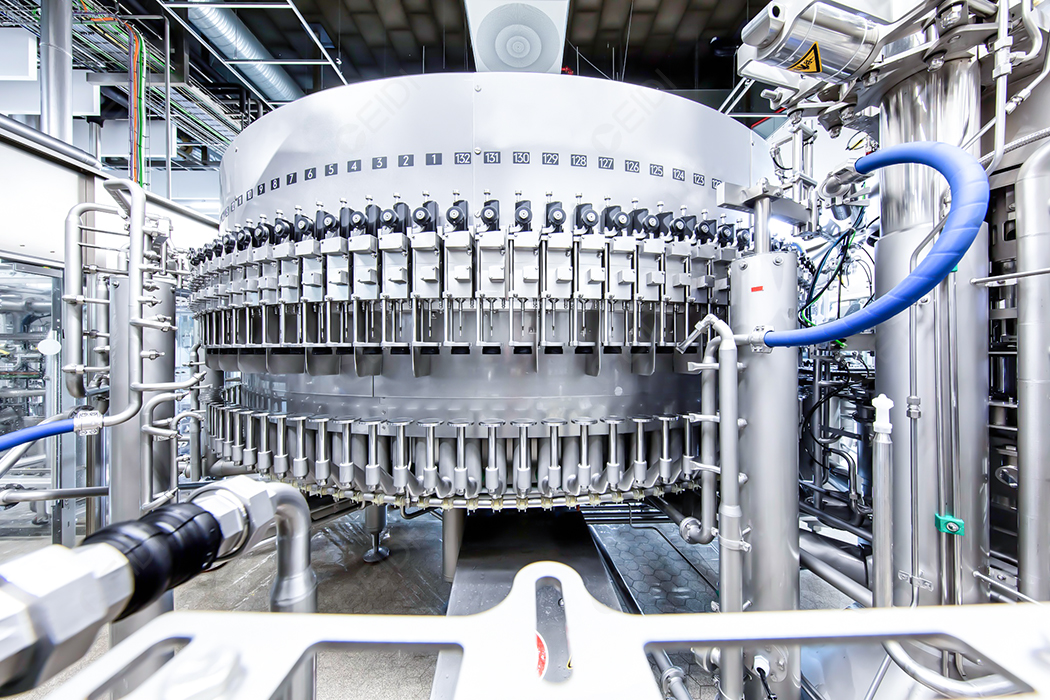

2. The beer production process and technology are: crushing of malt and powdering of auxiliary materials-saccharification and gelatinization-wort filtration-wort boiling (adding hops at the same time)-cyclotron precipitation-wort cooling-enter Fermentation tank (at the same time oxygenation and yeast)-main fermentation-post fermentation-beer filtration-packaging in the packaging department-output. The three stages of malt manufacturing, beer brewing, and beer filling are the main production processes. Among them, the beer aseptic filling workshop has strict cleanliness requirements, which are the key points of the entire plant design.

3. The process layout in the plant area should follow the principle of "three coordinations", that is, coordination of people flow and logistics, coordination of process flow, coordination of cleanliness level.

Design requirements for beer aseptic filling and purification workshop:

Since the food/beverage aseptic clean workshop requires the separation of people and materials, and maintains the static pressure gradient of each clean operation room, the important parameters of the brewery are required to meet the following purification requirements:

1. Use the familiar cleanliness to define the standard. The beer aseptic filling and purification workshop should be equipped with 100,000 grades (generally 15-20 times/H) and 10,000 grades of air changes (generally 20-30 times/H). ), three levels of local thousand level (the number of air changes is up to 50 times/H).

2. The temperature required for cleanliness of class 10,000 and above is generally 20-25°C, humidity is generally 45%-65%, and the temperature of cleanliness of 10,000 and below is generally 18-25°C, and humidity is generally 50%-65%.

3. Beer aseptic filling 10,000-level purification workshop area includes the entire filling room, from the bottle washing machine to the capping machine, of which the 100,000-level clean room area is the bottle transfer room, and the second half of the filling machine is to the capping outlet Use local aseptic air blower.

4. The air purification system of the aseptic filling and purification workshop includes ventilation, air filtration, and air cooling and heating adjustment. The process flow of most air conditioning units is generally: return fan → exhaust return air, intake fresh air → primary effect filter → surface cold removal Water → blower → medium efficiency filtration → silencer → high efficiency filtration → clean room.

In the "Industrial Structure Adjustment Guidance Catalog (2019 Edition)", the beer industry "beer bottling production lines with a production capacity of less than 18,000 bottles/hour" (restricted) and "glass bottle beer with a production capacity of less than 12,000 bottles/hour" have been cancelled. "Filling production line" (belonging to the obsolete category). In other words, in the future society, there will be more small craft breweries springing up like mushrooms. Clean project builders who carry the banner of construction like CEIDI have a long way to go to create standards, safety, and sustainability for Chinese clean project users. Development of the working environment.